Catalog

Products

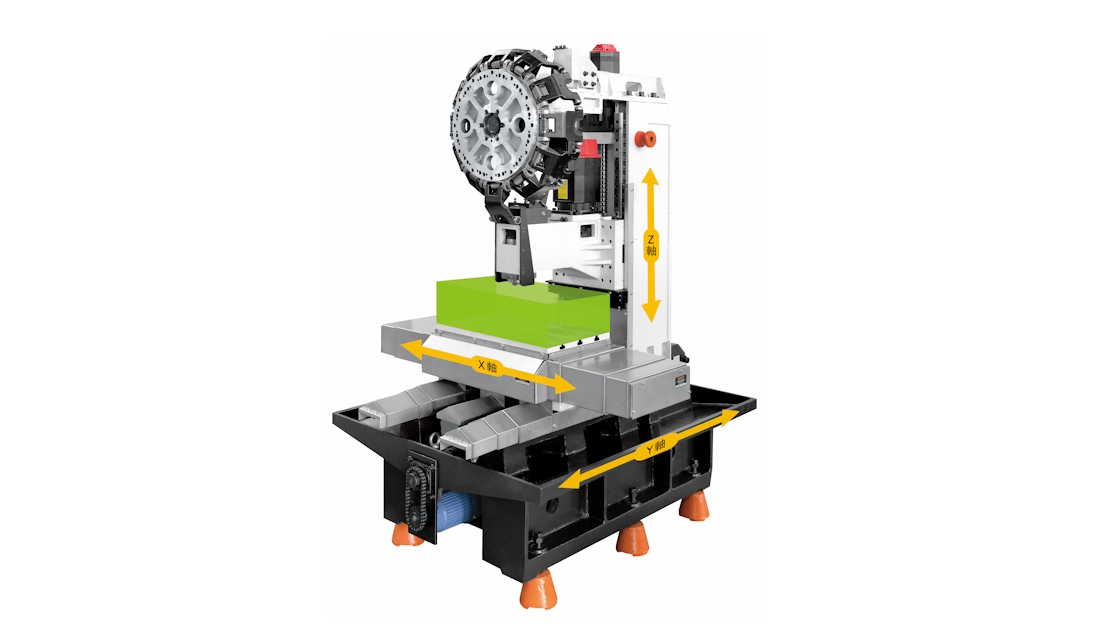

TAPPING SERIES High-Performance & High-Speed Drilling & Tapping Machines

ID:TAPPING SERIES

It is a high-performance, high-speed drilling and tapping machine, particularly suitable for precision machining and small mold processing, widely used in the automotive, motorcycle, and 3C electronics industries.

Machine Specifications

.High-speed spindle: Belt-driven direct drive system

.Spindle speed: 10000 RPM (standard) /12000 RPM (optional) /15000 RPM (optional). High-speed tool changer mechanism: Rotary turret 12T tool magazine / Umbrella type 14T/21T tool magazine (optional).

.Mitsubishi servo motor for quick tool change (T-Tl.2SEC)

.High rigidity structural design: providing sufficient stability for high-speed drilling, tapping, and milling processes. High-speed feed: 48/48/60 meters per minute.

TOOL TO TOOL 1.2 SEC. Quick Tool Change System

.Standard configuration: WINNER rotary turret 12T tool magazine

.Opting for Mitsubishi servo motor quick tool change reduces non-machining time, enhancing production efficiency.

.T-T1.25EC

High-precision axial feed system

.All three axes adopt high-precision roller linear guideways, with high load capacity and strong rigidity.

.Using imported high-precision ball screws, with low friction, high positioning accuracy, and long lifespan.

.Specialized model for mass production of small parts

.High-speed spindle: Belt-driven direct drive system

.Spindle speed: 10000 RPM (standard) /12000 RPM (optional) /15000 RPM (optional). High-speed tool changer mechanism: Rotary turret 12T tool magazine / Umbrella type 14T/21T tool magazine (optional).

.Mitsubishi servo motor for quick tool change (T-Tl.2SEC)

.High rigidity structural design: providing sufficient stability for high-speed drilling, tapping, and milling processes. High-speed feed: 48/48/60 meters per minute.

TOOL TO TOOL 1.2 SEC. Quick Tool Change System

.Standard configuration: WINNER rotary turret 12T tool magazine

.Opting for Mitsubishi servo motor quick tool change reduces non-machining time, enhancing production efficiency.

.T-T1.25EC

High-precision axial feed system

.All three axes adopt high-precision roller linear guideways, with high load capacity and strong rigidity.

.Using imported high-precision ball screws, with low friction, high positioning accuracy, and long lifespan.

.Specialized model for mass production of small parts

| Specifications | TAP-AP500 | TAP-AP750 | TAP-AP1000 | TAP-A510 | TAP-A650 | TAP-A750 |

| X Travel | 500 mm | 750 mm | 1000 mm | 510 mm | 650 mm | 750 mm |

| Y Travel | 350 mm | 450 mm | 560 mm | 350 mm | 400 mm | 450 mm |

| Z Travel | 300 mm | 300 mm | 300 mm | 300 mm | 400 mm | 400 mm |

| Spindle Nose to Table Surface | 150 - 450 mm | 150 - 450 mm | 170 - 470 mm | 170 - 470 mm | 150 - 550 mm | 150 - 550 mm |

| Spindle Center to Column | 420 mm | 420 mm | 660 mm | 463 mm | 545 mm | 545 mm |

| Table Size | 600 mm × 400 mm | 800 mm × 410 mm | 1100 mm × 500 mm | 600 mm × 360 mm | 700 mm × 410 mm | 800 mm × 460 mm |

| T-slots | 3 | 3 | 5 | 3 | 3 | 3 |

| T-slot Distance | 100 mm | 100 mm | 100 mm | 100 mm | 125 mm | 125 mm |

| T-slot Width | 18 mm | 18 mm | 18 mm | 18 mm | 18 mm | 18 mm |

| Table Loading Capacity | 200 kg | 260 kg | 500 kg | 200 kg | 260 kg | 260 kg |

| Spindle Transmission | Direct Connect | Direct Connect | Direct Connect | Belted | Belted | Belted |

| Spindel Speed | 60 - 10000 rpm | 60 - 10000 rpm | 60 - 10000 rpm | 60 - 10000 rpm | 60 - 10000 rpm | 60 - 10000 rpm |

| Spindle Taper | BT-30 | BT-30 | BT-30 | BT-30 | BT-40 | BT-40 |

| Axes Rapid Feed Rate | 48 × 48 × 36 m/min | 48 × 48 × 48 m/min | 36 × 36 × 36 m/min | 48 × 48 × 60 m/min | 48 × 48 × 48 m/min | 48 × 48 × 48 m/min |

| Max. Cutting Feed Rate | 10000 mm/min | 10000 mm/min | 10000 mm/min | 10000 mm/min | 10000 mm/min | 10000 mm/min |

| ATC Magazine | Umbrella Type | Umbrella Type | Umbrella Type | Turret Type | Turret Type | Turret Type |

| Tool Capacity | 14 T(Option Configuration 21 T) | 14 T(Option Configuration 21 T) | 14 T(Option Configuration 21 T) | 12 T | 12 T | 12 T |

| Floor Occupation | 1760 mm × 2180 mm | 2300 mm × 2880 mm | 2920 mm × 2950 mm | 1560 mm × 2120 mm | 2875 mm × 2480 mm | 2875 mm × 2480 mm |