Catalog

Products

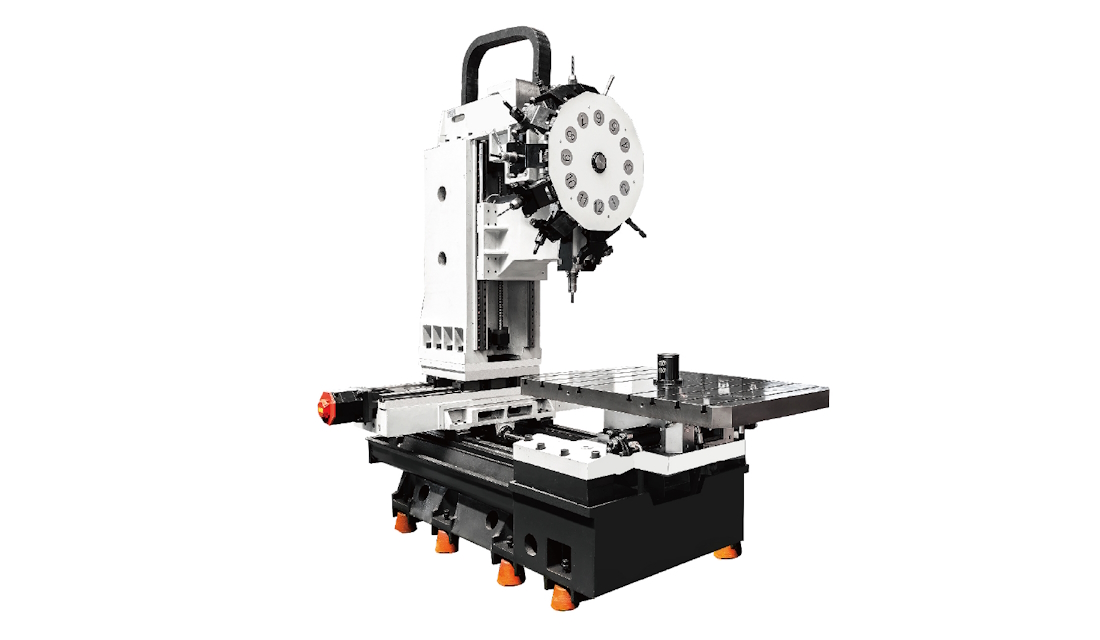

Tapping Center With Table Change

ID:ASP SERIES

Our exchange table drilling and tapping center features two worktables that can be swapped for use. While machining on one worktable, the next workpiece is prepared, allowing for very short switch times and continuous processing. This design enhances production efficiency and reduces idle time.

Designed specifically for automation, the feed port features front double doors, side monitoring doors, and open space above the worktable. For our drilling and tapping centers, the ASP510 and ASP750 models with two exchangeable worktables allow for uninterrupted workpiece replacement, thus enhancing production efficiency and making them the preferred choice for automated assembly lines.

High precision machining: Our exchange table drilling and tapping centers are equipped with precision positioning systems and advanced control technology to ensure high-precision drilling and tapping operations. Whether it's small hole machining or complex tapping, our equipment can guarantee high accuracy and consistent machining results, meeting your demand for high-quality products

High precision machining: Our exchange table drilling and tapping centers are equipped with precision positioning systems and advanced control technology to ensure high-precision drilling and tapping operations. Whether it's small hole machining or complex tapping, our equipment can guarantee high accuracy and consistent machining results, meeting your demand for high-quality products

| Specifications | ASP-A510 | ASP-A750 |

| X Travel | 510 mm | 750 mm |

| Y Travel | 350 mm | 410 mm |

| Z Travel | 300 mm | 400 mm |

| Spindle Nose to Table Surface | 150 - 450 mm | 170 - 570 mm |

| Spindle Center to Column | 463 mm | 545 mm |

| Table Size | 1090 mm × 700 mm | 1200 mm × 850 mm |

| T-slots | 10 | 8(Option: Threaded Hole) |

| T-slot Distance | 100 mm | 125 mm |

| T-slot Width | 18 mm | 18 mm |

| Table Loading Capacity | 200 kg | 300 kg |

| Spindle Transmission | Belted | Belted |

| Spindel Speed | 60 - 10000 rpm | 60 - 10000 rpm |

| Spindle Taper | BT-30 | BT-40 |

| Axes Rapid Feed Rate | 48 × 48 × 60 m/min | 36 × 36 × 36 m/min |

| Max. Cutting Feed Rate | 10000 mm/min | 10000 mm/min |

| ATC Magazine | Turret Type | Turret Type |

| Tool Capacity | 12 T | 12 T |

| Floor Occupation | 2000 mm × 3200 mm | 2360 mm × 3680 mm |