Catalog

Products

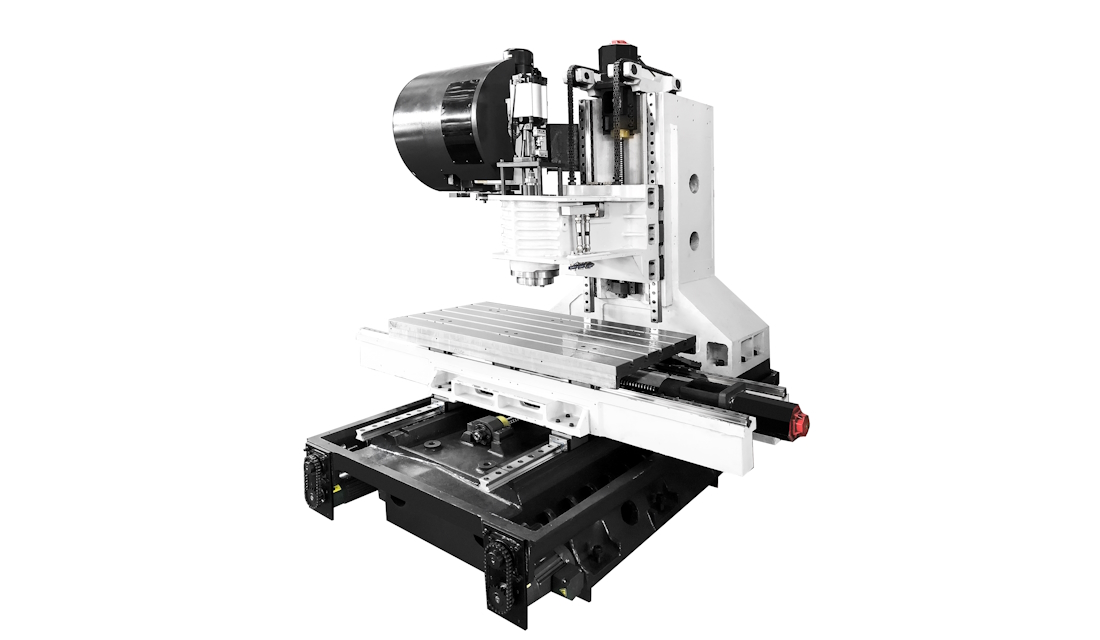

Standard Vertical Machining Center

ID:U1 SERIES

The U series high-efficiency vertical machining center, as the best-selling model of "WINNER" machine tools, adopts a completely new technological design to enhance the aesthetics and practicality of the machine tool. On the basis of retaining the original functions, overall optimization and upgrades have been carried out. It can maintain high-precision machining performance for a long time, with a high-rigidity structural design, improving the machining capability and production efficiency of the machine tool.

●The machine tool adopts a Mi Hanna cast iron design overall, providing optimal rigidity.

●The X/Y axis adopts high-precision linear guide rails, with fast speed, excellent accuracy, and long service life.

●The three axes use direct servo motor drive, combined with precision ball screw direct drive, strong rigidity, and excellent accuracy.

●The Z-axis spindle box weight balance device adopts guide rod guidance to reduce vibration, ensuring smooth vertical movement of the Z-axis.

The high-rigidity BTSO spindle series can be equipped with a gear head for increased rigidity, suitable for heavy cutting.

●The machine tool adopts a Mi Hanna cast iron design overall, providing optimal rigidity.

●The X/Y axis adopts high-precision linear guide rails, with fast speed, excellent accuracy, and long service life.

●The three axes use direct servo motor drive, combined with precision ball screw direct drive, strong rigidity, and excellent accuracy.

●The Z-axis spindle box weight balance device adopts guide rod guidance to reduce vibration, ensuring smooth vertical movement of the Z-axis.

The high-rigidity BTSO spindle series can be equipped with a gear head for increased rigidity, suitable for heavy cutting.

The U series high-efficiency vertical machining center, as the best-selling model of "WINNER" machine tools, utilizes new technological design to enhance the machine tool's aesthetics and practicality. It undergoes overall optimization and upgrades while retaining its original functions. It can maintain high-precision machining performance for an extended period due to its high-rigidity structural design, thereby improving the machining capability and production efficiency of the machine tool.

●The main structural components are made of high-quality Mi Hanna cast iron, ensuring stable organization and permanently guaranteeing quality.

●Castings undergo computer-calculated analysis using the finite element method, providing high rigidity to the machine through reasonable structural strength and reinforced ribs.

●The three axes are supported by linear guides, capable of supporting heavy loads and ensuring fast movement for precise positioning.

●The wide and solid base, along with the column's cruciform structure and widened and lengthened saddle, ensures the entire support of heavy loads, resulting in a solid structure capable of handling heavy machining loads.

●The spindle box is internally reinforced with ribs, and the proportion of contact length between the spindle box and the column is appropriate, providing stable support for the spindle.

●The main structural components are made of high-quality Mi Hanna cast iron, ensuring stable organization and permanently guaranteeing quality.

●Castings undergo computer-calculated analysis using the finite element method, providing high rigidity to the machine through reasonable structural strength and reinforced ribs.

●The three axes are supported by linear guides, capable of supporting heavy loads and ensuring fast movement for precise positioning.

●The wide and solid base, along with the column's cruciform structure and widened and lengthened saddle, ensures the entire support of heavy loads, resulting in a solid structure capable of handling heavy machining loads.

●The spindle box is internally reinforced with ribs, and the proportion of contact length between the spindle box and the column is appropriate, providing stable support for the spindle.

| Specifications | VMC-A/EU650 | VMC-A/EU750 | VMC-A/EU850 | VMC-A/EU1000 |

| X Travel | 650 mm | 750 mm | 850 mm | 1000 mm(o.p1100mm) |

| Y Travel | 410 mm | 450 mm | 560 mm | 600 mm |

| Z Travel | 510 mm | 510 mm | 560 mm | 600 mm |

| Spindle Nose to Table Surface | 150 - 660 mm | 150 - 660 mm | 140 - 700 mm | 100 - 700 mm |

| Spindle Center to Column | AU:530 mm EU:510 mm |

AU:530 mm EU:510 mm |

AU:660 mm EU:640 mm |

AU:660 mm EU:640 mm |

| Table Size | 700 mm × 410 mm | 800 mm × 460 mm | 1000 mm × 560 mm | 1150 mm × 600 mm |

| T-slots | 3 | 3 | 5 | 5 |

| T-slot Distance | 125 mm | 125 mm | 100 mm | 100 mm |

| T-slot Width | 18 mm | 18 mm | 18 mm | 18 mm |

| Table Loading Capacity | 300 kg | 300 kg | 500 kg | 600 kg |

| Spindle Transmission | Belted | Belted | Belted | Belted |

| Spindel Speed | 60 - 10000 rpm | 60 - 10000 rpm | 60 - 12000 rpm | 60 - 12000 rpm |

| Spindle Taper | BT-40 | BT-40 | BBT-40 | BBT-40 |

| Axes Rapid Feed Rate | AU:48 × 48 × 48 m/min EU:48 × 48 × 24 m/min |

AU:48 × 48 × 48 m/min EU:48 × 48 × 24 m/min |

AU:36 × 36 × 36 m/min EU:36 × 36 × 24 m/min |

AU:36 × 36 × 36 m/min EU:36 × 36 × 24 m/min |

| Max. Cutting Feed Rate | 10000 mm/min | 10000 mm/min | 10000 mm/min | 10000 mm/min |

| ATC Magazine | Arm Type | Arm Type | Arm Type | Arm Type |

| Tool Capacity | 24 T | 24 T | 24 T | 24 T |

| Floor Occupation | 2300 mm × 2800 mm | 2300 mm × 2800 mm | 2880 mm × 2890 mm | 2880 mm × 2890 mm |