Catalog

Products

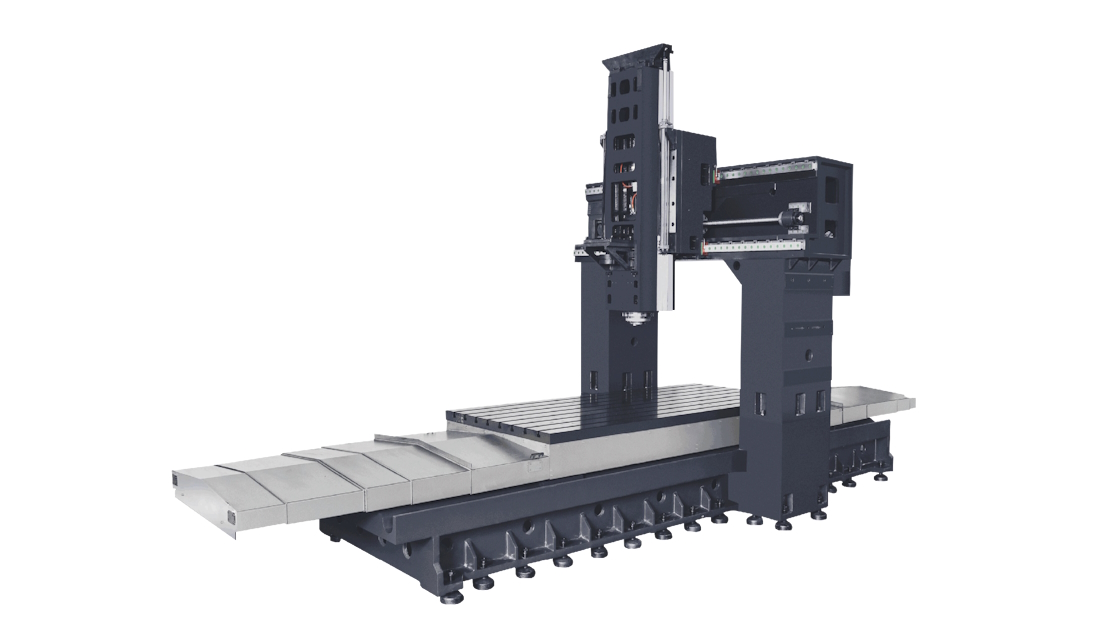

Double Column Machining Center

ID:NMC SERIES

Our gantry machining center features a robust gantry structure design, providing excellent rigidity and stability. This structure effectively eliminates vibration and deformation, ensuring high-precision machining results. With its spacious worktable and high load capacity, our gantry machining center is suitable for processing large workpieces. Whether milling, drilling, or boring, our equipment can easily meet various industry demands.

Machine Tool Characteristics:

●Stable Structure: Our gantry machining center features a robust gantry structure design, offering excellent rigidity and stability. This structure effectively eliminates vibration and deformation, ensuring high-precision machining results.

●Processing of Large Workpieces: With its spacious worktable and high load capacity, the gantry machining center is suitable for processing large workpieces. Whether milling, drilling, or boring, our equipment can easily handle various machining tasks.

●High Efficiency Machining: Equipped with a high-power spindle and rapid feed system, the gantry machining center achieves high-speed, high-efficiency machining. The fast cutting speed and feed rate, coupled with a high-rigidity structure, significantly shorten the machining cycle and improve production efficiency.

●Multi-axis Machining Capability: Our gantry machining center has multi-axis machining capability, enabling multi-sided machining of complex workpieces. With various optional side milling heads and universal angle heads, our equipment can perform complex surface machining and five-axis machining, providing more machining possibilities.

●Integral Beam Casting and High-rigidity Box-type Structure Design: The integral beam casting and high-rigidity box-type structure design, featuring a bridge-style arch design, effectively support vertical gravity and lateral resistance, ensuring optimal rigidity during cutting.

●Minimum Distance Design between Spindle Center and Z-axis Slide Rail: This design shortens the cutting force arm and significantly improves cutting rigidity.

●Dual High-seat Air Cylinder Counterbalance Configuration for Z-axis: The Z-axis is equipped with two sets of high-seat air cylinders for counterbalancing, synchronously balancing the weight of the spindle box.

| Specifications | NMC-1001 | NMC-2015 | NMC-3018 | NMC-3025 | NMC-4025 | NMC-6032 |

| X Travel | 1000 mm | 2000 mm | 3000 mm | 3000 mm | 4000 mm | 6000 mm |

| Y Travel | 800 mm | 1500 mm | 1800 mm | 2900 mm | 2900 mm | 3200 mm |

| Z Travel | 600 mm | 800 mm | 800 mm | 1000 mm | 1000 mm | 1000 mm |

| Spindle Nose to Table Surface | 120 - 620 mm | 170 - 970 mm | 180 - 980 mm | 300 - 1300 mm | 300 - 1300 mm | 200 - 1200 mm |

| Distance between Two Columns | 950mm | 1500 mm | 1850 mm | 2550mm | 2550mm | 3200 mm |

| Table Size | 1300 mm × 850 mm | 1200 mm × 2100 mm | 1500 mm × 3200 mm | 2100 mm × 3000 mm | 2100 mm × 4000 mm | 2500 mm × 6000 mm |

| T-slots | 8 | 7 | 10 | 11 | 11 | 10 |

| T-slot Distance | 100 mm | 150 mm | 150 mm | 180 mm | 180 mm | 220 mm |

| T-slot Width | 18 mm | 22 mm | 22 mm | 22 mm | 22 mm | 28 mm |

| Table Loading Capacity | 6000 kg | 4000 kg | 8000 kg | 10000 kg | 12000 kg | 20000 kg |

| Spindle Transmission | Direct Connect | Belted | Belted | Belted | Belted | Belted |

| Spindel Speed | 20 - 6000 rpm | 20 - 6000 rpm | 20 - 6000 rpm | 20 - 6000 rpm | 20 - 6000 rpm | 20 - 6000 rpm |

| Spindle Taper | BT-50(Φ190) | BT-50(Φ190) | BT-50(Φ190) | BT-50(Φ190) | BT-50(Φ190) | BT-50(Φ190) |

| Max. Torque Output | 159 / 636 N·m(Option) | 223 / 892 N·m(Option) | 223 / 892 N·m(Option) | 223 / 892 N·m(Option) | 223 / 892 N·m(Option) | 223 / 892 N·m(Option) |

| Gear Ratio | 1:1 / 1:4.0(Option) | 1:1 / 1:4.0(Option) | 1:1 / 1:4.0(Option) | 1:1 / 1:4.0(Option) | 1:1 / 1:4.0(Option) | 1:1 / 1:4.0(Option) |

| Axes Rapid Feed Rate | 24 × 24 × 24 m/min | 10 × 10 × 10 m/min | 8 × 10 × 10 m/min | 8 × 10 × 10 m/min | 8 × 10 × 10 m/min | 8 × 10 × 10 m/min |

| Max. Cutting Feed Rate | 10000 mm/min | 5000 mm/min | 5000 mm/min | 5000 mm/min | 5000 mm/min | 5000 mm/min |

| X Axis | 2 - 45 Roller | 2 - 55 Roller | 2 - 55 Roller | 2 - 55 Roller | 2 - 55 Roller | 2 - 55 Roller |

| Y Axis | 2 - 45 Roller | 2 - 55 Roller | 2 - 55 Roller | 2 - 55 Roller | 2 - 55 Roller | 2 - 55 Roller |

| Z Axis | 2 - 45 Roller | T-type bed | T-type bed | T-type bed | T-type bed | T-type bed |

| Floor Occupation | 3650 mm × 3600 mm | 4060 mm × 5360 mm | 4780 mm × 8325 mm | 512 mm × 8030 mm | 5220 mm × 9790 mm | 14500 mm × 5640 mm |