Catalog

Products

Five Axis Vertical Machining Center

ID:FMC SERIES

The FMC series of five-axis machining centers are designed with a foundation of standardization and a simple, reliable structure to achieve high-quality and powerful five-axis machining. With excellent machining performance, these machines provide customers with advanced five-axis machining equipment in highly competitive markets. The simultaneous five-axis movement reduces the number of workpiece clamping operations and fixture production, thereby reducing processing time and increasing efficiency. The C-axis worktable adopts a DD motor, providing high torque and rigidity while addressing traditional issues such as backlash and wear in worm gear mechanisms. The spindle, combined with high torque and high power output, features a high-rigidity structure, allowing for rough milling to finish milling to be completed on the same machine, making it suitable for processing hard materials and non-ferrous materials.

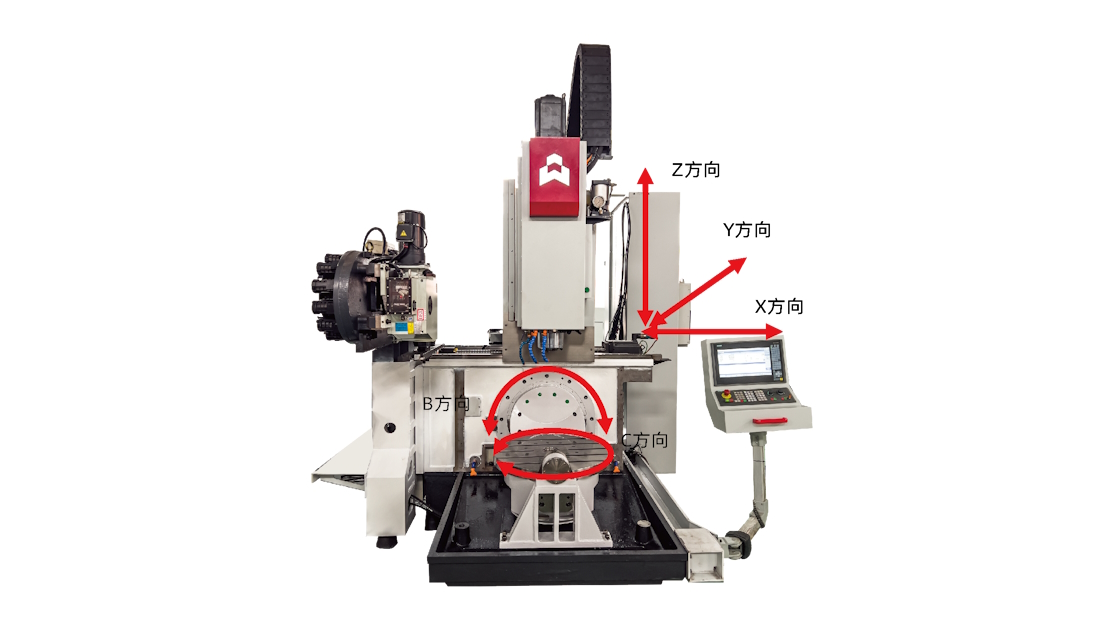

FMC-U650 Five-Axis Cradle Type-BC Axis The FMC series of five-axis machining centers feature a high-rigidity base capable of supporting single-swing B and C-axis rotations. The X/Y axes utilize a cross-slide design to ensure the optimal stability required for machining accuracy and surface quality, providing customers with the highest production efficiency.

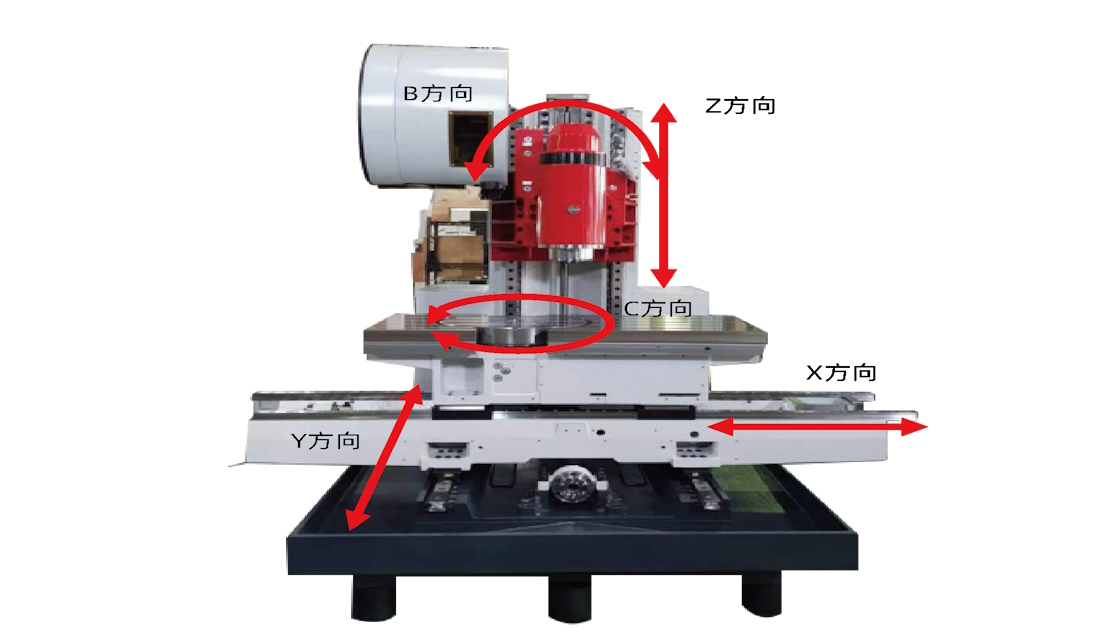

FMC-C600 Five-Axis Swivel Head Type-BC Axis Technical Features:

.Extremely High Efficiency: Suitable for simple to complex five-axis machining tasks.

.Exceptional Precision: X/Y/Z+B.C axes equipped with high-precision optical scales and powerful milling spindles: Direct drive transmission, with torque up to 80N.M, optional turret milling spindle, built-in electric spindle.

.Tool Magazine Capacity: Can accommodate storage of 40 tools (U650) and 32 tools (C600).

FMC-C600 Five-Axis Swivel Head Type-BC Axis Technical Features:

.Extremely High Efficiency: Suitable for simple to complex five-axis machining tasks.

.Exceptional Precision: X/Y/Z+B.C axes equipped with high-precision optical scales and powerful milling spindles: Direct drive transmission, with torque up to 80N.M, optional turret milling spindle, built-in electric spindle.

.Tool Magazine Capacity: Can accommodate storage of 40 tools (U650) and 32 tools (C600).

| Specifications | FMC-C600 | FMC-U650 |

| X Travel | 1200 mm(turning 1000mm) | 650 mm |

| Y Travel | 600 mm | 520 mm |

| Z Travel | 600 mm | 480 mm |

| B Travel | Swing Angle Range -100° ~ 100° | Tilting Angle Range -50° ~ 110° |

| C Travel | 0 - 360° | 0 - 360° |

| Spindle Nose to Table Surface | 140 - 740 mm | 150 - 630 mm |

| Spindle Center to Column | 765 mm | 650 mm |

| Table Size | 1200 mm × 700 mm( Turning version without square worktable) | NA |

| Rotate Table Diameter | 600 mm | 650 mm |

| T-slots | 5 | 5 |

| T-slot Distance | 125 mm | 100 mm |

| T-slot Width | 18 mm | 18 mm |

| Table Loading Capacity | 1000 kg | 300 kg |

| Spindle Transmission | Direct Drive | Direct Connect |

| Spindel Speed | 60 - 12000 rpm | 60 - 15000 rpm |

| Spindle Taper | BT-40/HSK 63 | BT-40/HSK 63 |

| Axes Rapid Feed Rate | 30 × 30 × 30 (turning40/40/36)m/min | 36 × 36 × 36 m/min |

| B/C Axes Rapid Rotate Rate | 50 / 50 (turning 50/800) rpm/min | 50 / 100 rpm/min |

| Max. Cutting Feed Rate | 10000 (turning20000) mm/min | 10000 mm/min |

| ATC Magazine | Arm Type | Arm Type |

| Tool Capacity | 40 T | 32 T |

| Floor Occupation | 3450 mm × 3300 mm | 3100 mm × 2650 mm |