Catalog

Products

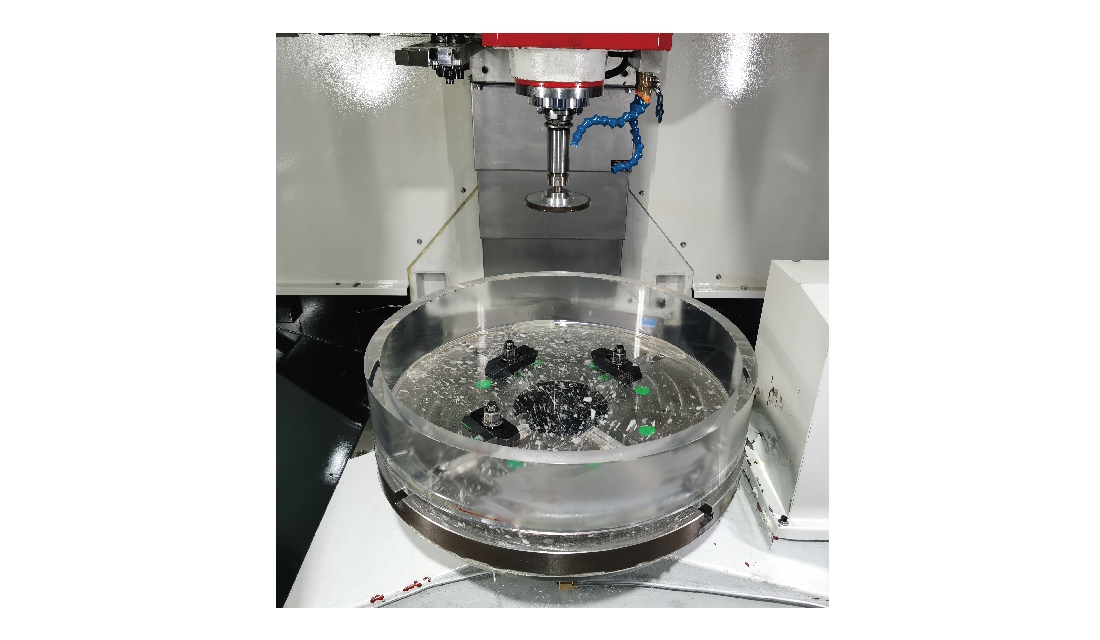

Vertical Grinding Machining Center

ID:VGM SERIES

Vertical grinding machining centers are specialized equipment capable of both milling and grinding operations. In addition to typical drilling and cutting functions, they can also perform grinding operations on circular workpieces both internally and externally. Widely used in the processing of hard and brittle materials, they enhance machining efficiency and precision.

Adding a direct-drive torque rotary table as an option enhances the stability and machining efficiency of the product. Vertical grinding machining centers are highly efficient and precise machining equipment designed specifically for achieving high-precision and high-efficiency grinding operations. They are widely used in various fields such as mold manufacturing, aerospace, automotive components, medical devices, etc. These centers can process various materials including metals, plastics, ceramics, etc., and achieve high-precision, high-surface-quality machining results.

| Specifications | VGM-600 |

| X Travel | NA |

| Y Travel | 600 mm (-Y:100 / +Y:500) |

| Z Travel | 510 mm |

| Spindle Nose to Table Surface | 40 - 550 mm |

| Spindle Center to Column | 530 mm |

| Table Diameter | 600 mm |

| T-slots | 4 |

| T-slot Distance | 45° |

| T-slot Width | 18 mm |

| Table Loading Capacity | 300 kg |

| Spindle Transmission | Direct Connect |

| Spindel Speed | 60 - 12000 rpm |

| Spindle Taper | BT-40 |

| Transmission | Belted |

| Speed | 50 - 100 rpm |

| Axes Rapid Feed Rate | 30 × 48 m/min |

| Max. Cutting Feed Rate | 10000 mm/min |

| ATC Magazine | Arm Type |

| Tool Capacity | 24 T |

| Floor Occupation | 2200 mm × 3040 mm |