Professional Machine Tool Equipment Manufacturer

Electronics - 3C Manufacturing

Specialized machinery for mass-producing small parts, tailored for electronic 3C product applications. It integrates milling, drilling, and tapping operations into a single process, eliminating the need for separate setups. Equipped with an automatic tool changer, it boosts productivity by 30% by allowing parts to be changed without interrupting production.

Metal Processing

Widely used in metal processing, our machines cater to the needs of the automotive, mold-making, construction machinery, wind energy, and solar industries. We offer a range of machines including vertical machining centers, horizontal machining centers, gantry machining centers, moving column machining centers, and dual spindle machining centers.

Aerospace Machining

For complex surface and impeller machining applications, we introduce five-axis machining centers. These machines enable multi-sided machining in a single setup and support simultaneous five-axis machining for increased efficiency and precision.

Applications for machining hard and brittle materials

Enhancing overall rigidity to meet material processing requirements, improving equipment precision, and incorporating high protective measures to effectively strengthen equipment stability. Additionally, introducing dedicated grinding machines tailored to specific industrial applications.

Automation and Smart Factory

In response to the development of Industry 4.0 and the trend towards AI intelligence, we can provide customers with comprehensive solutions ranging from CAPP management, flexible line management, production management, to intelligent monitoring of equipment and quality traceability.

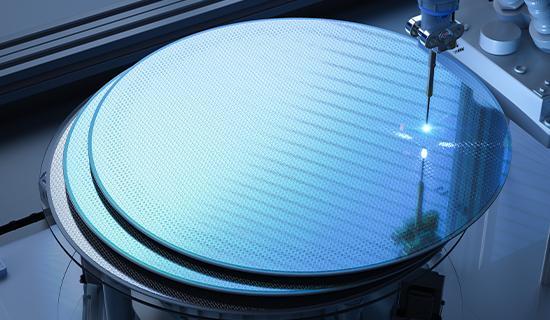

Electronics - 3C Manufacturing

Specialized machinery for mass-producing small parts, tailored for electronic 3C product applications. It integrates milling, drilling, and tapping operations into a single process, eliminating the need for separate setups. Equipped with an automatic tool changer, it boosts productivity by 30% by allowing parts to be changed without interrupting production.

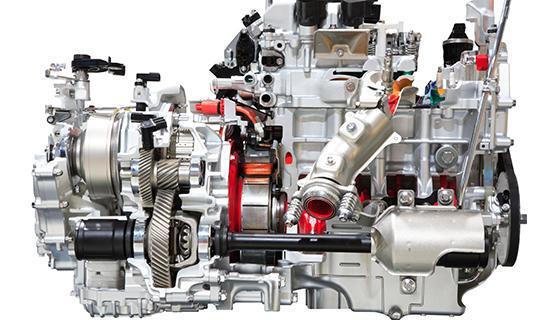

Metal Processing

Widely used in metal processing, our machines cater to the needs of the automotive, mold-making, construction machinery, wind energy, and solar industries. We offer a range of machines including vertical machining centers, horizontal machining centers, gantry machining centers, moving column machining centers, and dual spindle machining centers.

Aerospace Machining

For complex surface and impeller machining applications, we introduce five-axis machining centers. These machines enable multi-sided machining in a single setup and support simultaneous five-axis machining for increased efficiency and precision.

Applications for machining hard and brittle materials

Enhancing overall rigidity to meet material processing requirements, improving equipment precision, and incorporating high protective measures to effectively strengthen equipment stability. Additionally, introducing dedicated grinding machines tailored to specific industrial applications.

Automation and Smart Factory

In response to the development of Industry 4.0 and the trend towards AI intelligence, we can provide customers with comprehensive solutions ranging from CAPP management, flexible line management, production management, to intelligent monitoring of equipment and quality traceability.

Electronics - 3C Manufacturing

Specialized machinery for mass-producing small parts, tailored for electronic 3C product applications. It integrates milling, drilling, and tapping operations into a single process, eliminating the need for separate setups. Equipped with an automatic tool changer, it boosts productivity by 30% by allowing parts to be changed without interrupting production.

Metal Processing

Widely used in metal processing, our machines cater to the needs of the automotive, mold-making, construction machinery, wind energy, and solar industries. We offer a range of machines including vertical machining centers, horizontal machining centers, gantry machining centers, moving column machining centers, and dual spindle machining centers.

Aerospace Machining

For complex surface and impeller machining applications, we introduce five-axis machining centers. These machines enable multi-sided machining in a single setup and support simultaneous five-axis machining for increased efficiency and precision.

Applications for machining hard and brittle materials

Enhancing overall rigidity to meet material processing requirements, improving equipment precision, and incorporating high protective measures to effectively strengthen equipment stability. Additionally, introducing dedicated grinding machines tailored to specific industrial applications.

Automation and Smart Factory

In response to the development of Industry 4.0 and the trend towards AI intelligence, we can provide customers with comprehensive solutions ranging from CAPP management, flexible line management, production management, to intelligent monitoring of equipment and quality traceability.

Professional manufacturer of machine tool equipment and expert in electromechanical integration applications

Product Advantages and Features:

The high-rigidity and high-precision structural design can meet various processing needs.

The main structure adopts high-quality Meehanite cast iron HT300, with stable organization and the addition of rare metal elements, ensuring permanent quality.

The wide and solid base, along with the column in a dovetail-shaped structure, and the widened and lengthened saddle, all designed with full support for heavy loads, ensure the structural solidity and the capability to withstand heavy loads during machining.

Using high-quality ball screws from Germany and Japan, along with high-rigidity roller linear guideways, ensures long lifespan and high precision.

Modular design with fully enclosed sheet metal protection prevents the spread of cutting dust and oil mist.

News

Recruitment

Looking for nationwide distribution agents and technical service personnel

view more